Laser Welder vs TIG Welding: Which is Best for Your Factory?

When choosing between a Laser Welder vs TIG Welding system for your 2026 production line, the results in speed and quality are the most important factors. A high-performance Fiber Laser Welder offers significant advantages over traditional methods, especially in terms of efficiency and labor savings.

Direct Cost & Performance Comparison

| Comparison Items | Traditional TIG Welding | RIVOMACH Laser Welder | Benefit |

|---|---|---|---|

| Welding Speed | 0.2 – 0.5 m/min | 2.0 – 5.0 m/min | 10X Faster |

| Labor Skill | Highly skilled welder required | 1-hour training for beginners | Save 60% Labor Cost |

| Post-Processing | Heavy grinding & polishing | Zero post-processing | Save Consumables |

| Heat Affected Zone | Large (Causes deformation) | Minimal (Precise & Clean) | 95% Less Scrap |

Need a quick quote for your material? Chat with our engineer via WhatsApp

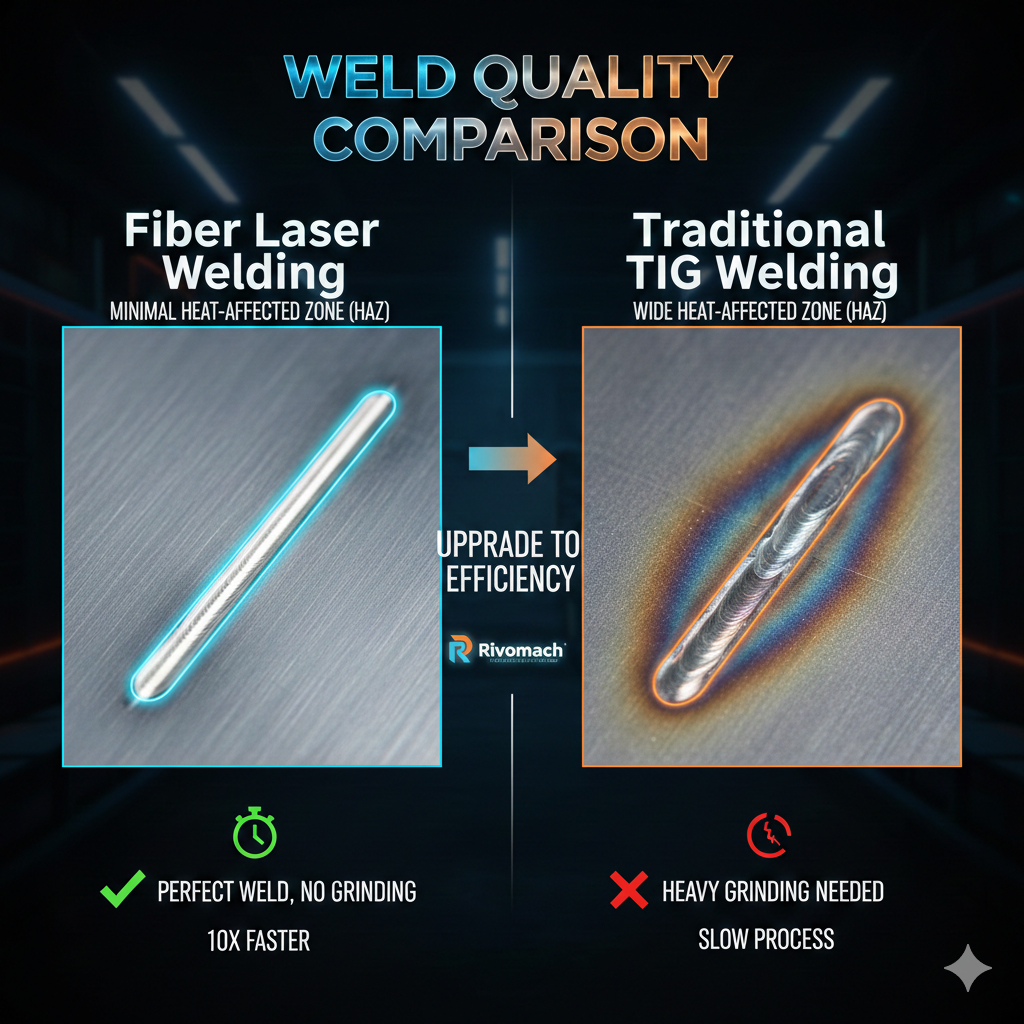

Figure 1: Side-by-side comparison of Laser Welder vs TIG Welding quality.

Direct Benefits of Upgrading

As seen in the Laser Welder vs TIG Welding comparison image above, the laser system creates a much narrower heat-affected zone (HAZ). This technology allows for 10X faster production and zero post-processing.

For more deep technical insights, you can explore the latest advancements in laser welding.

Get a Customized ROI Analysis

Switch from TIG to Fiber Laser Efficiency Today

To provide the most accurate recommendation, please share your material type, thickness, and product with our engineers.

FOB Price | CE Certified | 2-Year Global Warranty | Free Technical Support