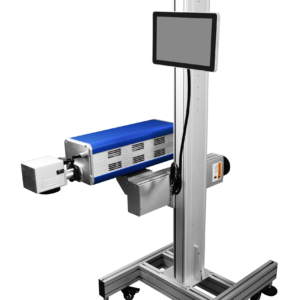

What is a CO2 Laser Marking Machine?

A CO2 laser marking machine is an automated precision engraving system utilizing a carbon dioxide gas laser with a wavelength of 10.64μm. By focusing a high-energy laser beam onto non-metal surfaces, it vaporizes the top layer of the material to reveal deep-seated patterns, text, or logos. This thermal process creates permanent, high-contrast marks that are resistant to wear and chemicals.

Applicable Materials & Industries

Compatible Materials:

Wood, Plywood, MDF, Bamboo, Leather, Fabric, Paper, Rubber, PMMA, ABS, PVC, Epoxy Resin, Plastic, Acrylic, Glass, Architectural Ceramics, and various organic materials.

Key Industries:

Medical, Horology, Eyewear, Instrumentation, Apparel, Leather Goods, Packaging (Food & Beverage), Cosmetics, Electronic Components, and Communication Equipment Manufacturing.

Working Principle

The CO2 laser is a gas laser that uses CO2 as the active medium. The gas is filled into a discharge tube, and a high voltage is applied. This creates a glow discharge, causing the gas molecules to release laser light. After amplifying this energy, it forms a powerful laser beam. The computer-controlled galvanometer then moves the mirrors to guide the beam, creating precise marks through localized vaporization of the target material.

Technical Specifications

| Laser Power Options | 20W / 30W / 60W / 80W / 100W / 150W / 200W |

| Laser Wavelength | 10.6 μm |

| Marking Speed | ≤ 12,000 mm/s |

| Cooling System | Air Cooling / Water Cooling (Based on Power) |

Pros (Advantages)

- Non-contact processing: No damage to the workpiece.

- Zero Consumables: Low operating costs.

- Permanent Marking: Resistant to environmental wear.

- High Efficiency: Ideal for mass production lines.

Cons (Limitations)

- Not suitable for direct marking on bare metals.

- Requires proper ventilation for fumes.

Maintenance Checklist

1. Lens Cleaning: Clean the field lens daily with lens tissue and alcohol to prevent dust burn-in.

2. Cooling System: Ensure vents are clear of dust. For water-cooled units, change pure water weekly.

3. Power Stability: Use a voltage stabilizer to protect the laser source from surges.

Troubleshooting & FAQ

Q: Why is the laser power dropping?

A: Check if the laser tube is reaching its end of life or if the power supply voltage is unstable. Also, ensure the lenses are not contaminated.

Q: What causes uneven marking depth?

A: This is usually due to the work surface not being perfectly level or the focal length being incorrectly set.

Ready to Upgrade Your Production?

Inquiry -> Quote -> Process Evaluation -> Manufacturing -> Global Shipping

Contact the RIVOMACH Jinan Team today for 2026 factory-direct pricing.