Solutions

While many suppliers specialize in only one area, RIVOMACH provides a comprehensive ecosystem covering laser cutting, welding, marking, and cleaning. Specifically, we understand that these four processes are the backbone of modern metal fabrication. Furthermore, our engineers customize each system to ensure seamless integration into your specific production line. Consequently, you receive a unified technical standard that simplifies maintenance and maximizes efficiency.

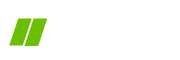

Precision Laser Cutting Solutions

Although speed is important, we prioritize edge quality and long-term machine stability in our cutting systems. Specifically, our fiber laser cutters are optimized for both thin sheets and thick plates. Therefore, you can achieve complex geometries with zero secondary processing needed.While we serve a diverse range of clients, our high-speed cutting systems are specifically optimized for these four major industrial sectors:

Advanced Laser Welding Systems

Instead of relying on traditional, slow welding methods, our handheld and automated laser welders offer 4x higher productivity. Moreover, the high-density energy beam ensures deep penetration with minimal thermal deformation. As a result, even intricate joints become incredibly strong and aesthetically perfect.Because our welding technology prioritizes precision and strength, it has become the standard solution for the following industries:

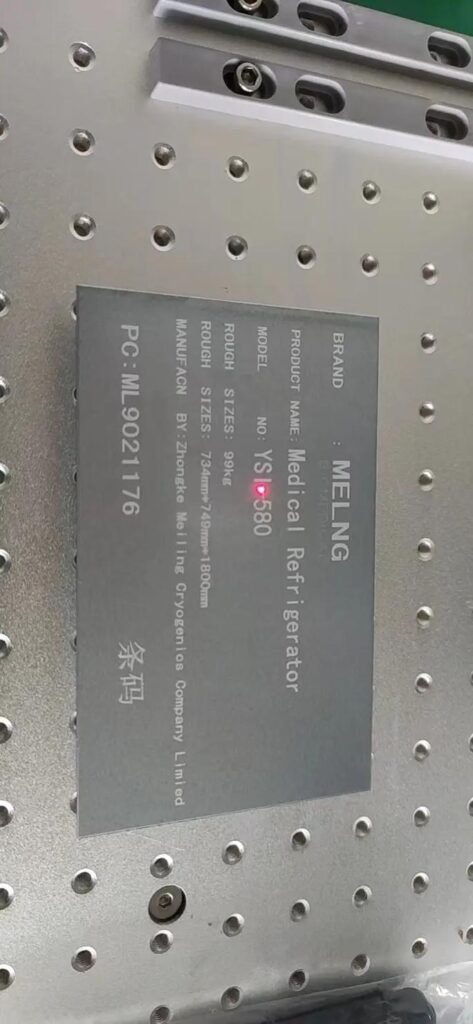

High-Speed Laser Marking & Traceability

Since industrial traceability is crucial for modern quality control, our marking solutions offer permanent, high-contrast results on diverse materials. In addition, our systems support high-speed galvo technology for integration into automated lines. Accordingly, you can track every component throughout its entire lifecycle.Since permanent traceability is essential for modern quality control, our marking systems provide high-speed integration for:

Eco-Friendly Laser Cleaning Technology

Because chemical solvents and abrasive blasting are costly and hazardous, we offer a non-contact laser cleaning alternative. Specifically, this technology removes rust, oil, and coatings without damaging the substrate. Ultimately, it provides a sustainable and cost-effective way to prepare surfaces for the next production stage.Although traditional cleaning is often hazardous, our non-contact laser technology offers a safer alternative for these professional sectors:

Auxiliary & Support Systems

While the laser source provides the core power, our professional auxiliary systems ensure the precision, safety, and long-term cost-efficiency of your entire production line.

High-Purity Nitrogen Generators

Specifically, our nitrogen generation systems are designed for fiber laser cutting applications where edge quality is paramount. Instead of relying on expensive liquid nitrogen, our on-site solution provides a continuous flow of high-purity gas.

- ✔ 99.99% Purity: Ensures oxidation-free and bright cutting edges.

- ✔ Cost Reduction: Lowers gas-related operational expenses by up to 40%.

- ✔ On-Demand Supply: Continuous 24/7 gas supply for heavy industrial workloads.

Consequently, you achieve a professional finish on stainless steel and aluminum with significantly lower overhead costs.

Industrial Dust Collection Systems

Because laser cutting and welding generate fine particulates, a robust extraction system is essential. Furthermore, our dust collectors utilize advanced HEPA filtration to protect your laser’s optical components from contamination.

- ✔ High Airflow: Rapidly removes smoke, dust, and odors during processing.

- ✔ Auto-Cleaning: Intelligent pulse-jet filter cleaning for minimal maintenance.

- ✔ Safety Compliance: Meets international environmental and OSHA standards.

Therefore, maintaining a clean environment not only protects your workers but also extends the precision lifespan of your equipment.

Need a Complete Turnkey Solution?

Although we offer individual units, our expertise lies in integrating these systems into a seamless production hub. Accordingly, contact our Jinan-based engineering team today.

REQUEST TECHNICAL PROPOSAL